@ShahidNShah

Factory floors generate enormous amounts of data. The problem is most of it stays trapped inside individual machines, basically inaccessible to anyone who could actually use it.

Production managers know their equipment logs’ performance metrics constantly. Cycle times, error codes, temperature readings, and throughput counts. All of it sitting there. But pulling that information out, processing it, getting it in front of decision-makers? That’s where most operations hit a wall.

Specialized manufacturing analytics platforms exist to solve this exact problem. They connect directly to production equipment, aggregate the data automatically, and turn raw numbers into something useful.

It’s the same visibility problem hospitals face, just with different “machines.” In a busy clinic, patient flow, appointment schedules, and wait times are constantly changing, but that information often stays stuck in individual systems or behind staff logins. Many healthcare facilities now surface the essentials on digital signage patient wait times, schedules, and service updates—so patients and staff can see what’s happening without chasing someone down for an update.

The phrase “machine integration” gets thrown around a lot in manufacturing tech circles. What it means in practice is software that talks to your equipment without someone manually logging data into a spreadsheet. Which, honestly, is still how a lot of places operate.

Industrial equipment communicates through specific protocols. Modbus has been around forever. OPC-UA is newer and more flexible. MQTT works well for IoT sensor networks. And then you’ve got proprietary systems from major equipment manufacturers adding another layer of fun.

A capable analytics platform needs to speak these languages. It connects to PLCs, pulling live operational data. It ingests streams from IoT sensors attached to equipment. It syncs with your MES and ERP systems so production data connects to business context.

This isn’t simple stuff. Getting reliable data flowing from diverse equipment into a unified analytics environment takes real implementation work. Expect it to take time.

In healthcare, “integration” is often less about PLCs and more about getting critical information out to the right places fast. A common example is waiting areas and exam rooms: clinics use screens to stream appointment reminders, telehealth information, and wellness messaging so patients get timely updates without staff repeating the same guidance all day. It’s a lighter-weight integration than industrial protocols, but the goal is identical reduce manual communication and make operational data usable in real time.

Several vendors have built their businesses around manufacturing analytics with machine connectivity. They’ve done the hard work of building industrial protocol support and data processing pipelines.

Sight Machine offers cloud-based analytics with strong equipment connectivity across industries. Tulip takes a different approach with no-code tools for building custom manufacturing applications. MachineMetrics focuses specifically on machine monitoring and utilization analytics.

Rockwell Automation’s FactoryTalk integrates deeply with their equipment ecosystem. Augury specializes in machine health prediction using vibration and acoustic analysis. Parsable connects worker platforms with equipment data.

What these platforms share is purpose-built architecture for industrial environments. They handle the complexity of collecting data from diverse equipment types, processing it in near real-time, and making it available for analysis.

Implementation timelines vary considerably. Simple single-line pilots might come together in a few weeks. Facility-wide deployments with complex equipment mixes typically run 3-6 months.

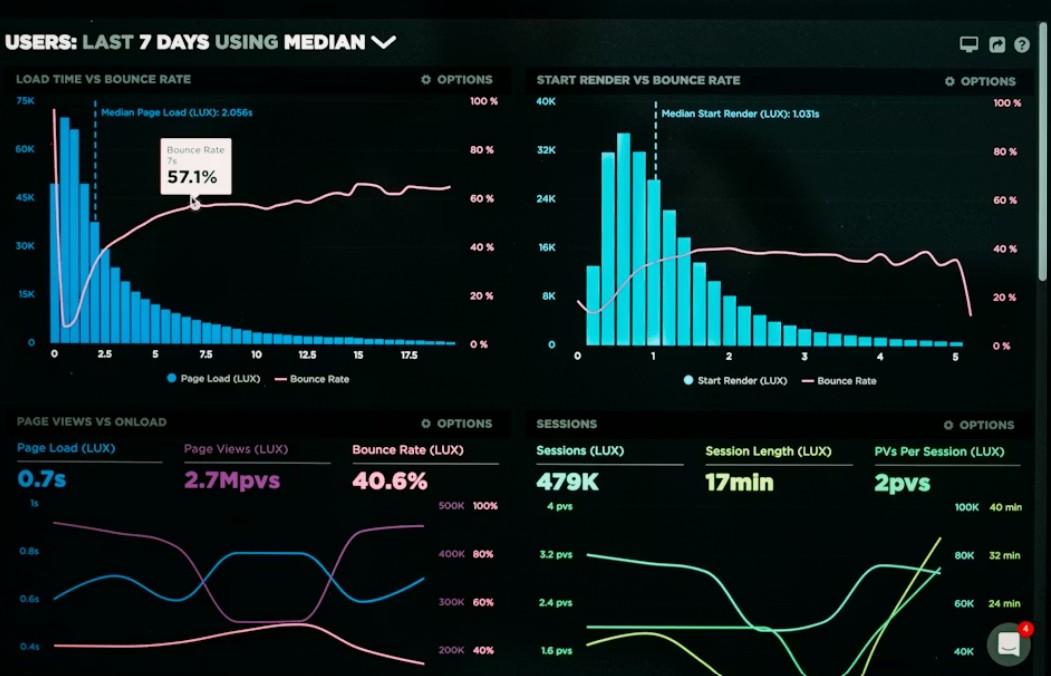

Overall Equipment Effectiveness remains the standard measure for production performance. It combines availability, performance, and quality into a single percentage that tells you how well your equipment is actually producing.

Availability tracks whether the machine was running when it was supposed to be. Performance compares actual output speed to theoretical maximum. Quality measures how many good units came out versus total units produced.

Multiply those three together and you get OEE. World-class operations hit 85% or higher. Most factories? Somewhere between 40-60%. That gap represents real money sitting on the table.

Analytics platforms calculate OEE automatically from connected equipment data. They track runtime, count output, and flag quality issues without anyone filling out paper forms or updating spreadsheets. The accuracy improvement alone often justifies the investment.

Unplanned downtime is expensive. Machine stops unexpectedly, production halts, maintenance scrambles to figure out what happened, parts get ordered on rush delivery. Costs pile up fast.

Predictive maintenance uses equipment sensor data to identify problems before failures occur. Vibration patterns indicate bearing wear. Temperature trends reveal cooling system degradation. Current draw changes signal motor issues.

The analytics aren’t magic, though. They require historical data to train algorithms on what normal looks like for your specific equipment. Figure on 3-6 months of data collection before predictions become reliable. Patience required.

But once calibrated, these systems catch problems weeks before breakdown. Maintenance happens during scheduled downtime instead of emergency stops. The reduction in unplanned downtime pays for a lot of software.

Collecting and analyzing production data solves one problem. Getting that information in front of the people who need it? That’s a different challenge.

Not everyone on a factory floor has a computer terminal. Operators, supervisors, and maintenance techs. They need visibility without logging into software every time something changes. This is where display solutions come into play.

Dashboards for manufacturing industry applications pull processed data from analytics platforms and broadcast it on screens throughout facilities. Production counts versus targets. Current OEE scores. Quality metrics. Safety milestones.

The analytics platform does the heavy lifting of data collection and processing. Display systems handle the communication layer, making insights visible to everyone who needs them.

Think of it as two distinct functions working together. One system figures out what’s happening. The other makes sure people know about it.

Manufacturing analytics platforms can’t operate in isolation. They need to connect with ERP systems for cost accounting and inventory. They need MES integration for production scheduling. Quality management systems need defect data. Maintenance systems need predictive alerts.

API connections handle most of this bidirectionally. Data flows from equipment into the analytics platform. Processed insights flow back out to planning and execution systems.

Verify these integration capabilities during evaluation. Vendors will tell you they can connect to anything. That’s what they do. Ask for demonstrations showing actual data flowing between your specific systems. Promises without proof aren’t worth much.

Cloud platforms dominate new deployments for practical reasons. No server infrastructure to buy and maintain. Automatic updates. Easy scaling as you add equipment or facilities. Lower total cost of ownership over a multi-year horizon.

On-premise still makes sense for specific situations. High-security facilities with strict data policies. Locations with unreliable internet connectivity. Regulatory requirements mandating local data storage.

Edge computing offers a middle path. Local devices process data at the facility level. Cloud systems aggregate data across locations for enterprise-wide visibility. You get the benefits of both approaches.

Production problems don’t wait for convenient timing. Plant managers need visibility when they’re traveling, at customer sites, or dealing with something at 2am from home.

Any modern platform should work properly on phones and tablets. Not just technically functional, but actually usable. Dashboards that require pinching and zooming to read? Not practical. Alerts that can’t be acknowledged from mobile? Creates unnecessary delays when people are already stressed.

Test mobile apps during evaluation using your actual phones. Performance varies more than you’d expect between platforms.

Pricing models vary across vendors. Per-user licensing. Per-machine fees. Feature tiers. Volume discounts. Comparing apples to apples takes work.

Beyond the subscription, factor implementation services and integration development. Data cleanup if your existing records have quality issues. Training for staff who’ll manage the system. Content creation for custom dashboards and reports. It adds up.

A single-line pilot at one facility looks different financially than a multi-site enterprise deployment. Scope drives cost more than any other variable.

ROI calculations for manufacturing analytics typically center on downtime reduction. Even modest improvements pay for software quickly when you calculate the cost of lost production.

Other returns include reduced scrap from better quality monitoring, increased throughput from OEE improvements, and lower maintenance costs through predictive approaches.

Most manufacturers see positive ROI within 12-24 months. Results depend heavily on current efficiency levels, though. Operations already running well have less room to improve. Operations with significant gaps see faster returns. Know where you’re starting from.

Healthcare teams often measure similar “return,” just with different outcomes. Digital signage in clinics is commonly used to reduce perceived and actual waiting friction, improve communication, and raise patient satisfaction by keeping patients informed with wait times, reminders, and service information rather than leaving them in the dark.

Start with your actual situation. What equipment do you have? What protocols does it use? What systems does the analytics platform need to integrate with? What problems are you actually trying to solve?

Request demonstrations that show real connectivity to equipment similar to yours. Ask about implementation timelines for facilities comparable in complexity. Talk to reference customers in your industry.

Pilots reduce risk. Test at a single line or facility before committing to broader deployment. Prove the technology works in your environment before scaling up.

The platforms that look good in presentations don’t always perform in production. Evaluation takes effort. But making the wrong choice costs more in the long run.

Chief Editor - Medigy & HealthcareGuys.

If you’ve been hurt in an accident near Gwinnett Place Mall in GA, your first instinct might be to tough it out or wait until the weekend to see how you feel. It’s a natural human response …

Posted Jan 21, 2026 Legal & Compliance Medical Management

Connecting innovation decision makers to authoritative information, institutions, people and insights.

Medigy accurately delivers healthcare and technology information, news and insight from around the world.

Medigy surfaces the world's best crowdsourced health tech offerings with social interactions and peer reviews.

© 2026 Netspective Foundation, Inc. All Rights Reserved.

Built on Mar 6, 2026 at 2:19pm