@ShahidNShah

Not long ago, digital tools in dentistry were treated like optional upgrades. A scanner in one treatment room, a mill tucked away in the back, maybe a planning program on a single overworked computer. Nice to have, but not essential.

That thinking doesn’t hold up anymore. Patients now expect speed, transparency, and fewer visits. Clinicians want predictable results with less friction. Owners need every piece of equipment to pay its way. Put all of that together, and digital dentistry stops being “cool tech” and becomes a strategic decision about how the practice actually functions.

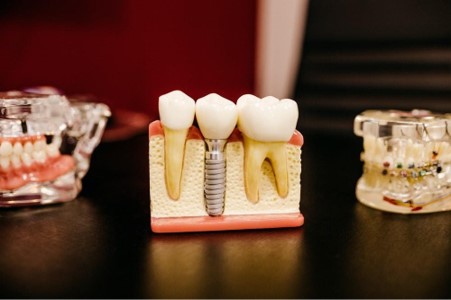

Most high-functioning digital practices end up with the same core pieces, even if they buy them in different orders. First are the intraoral and extraoral scanners. They replace trays and impression material with clean 3D data that can be captured quickly and reused. When those scanners talk directly to design software and practice management systems, they become the front door for diagnostics, patient education, and treatment planning.

Next comes CAD design and planning software. This is where raw scans turn into real-world plans: crowns, onlays, implant restorations, bite adjustments. Instead of guessing, clinicians can simulate occlusion, refine contacts, and standardize designs so remakes and last‑minute adjustments turn into the exception rather than the rule.

Chairside mills and printers are the visible heroes of the same‑day workflow. A patient walks in with a cracked tooth and a few hours later walks out with a permanent restoration. But that experience only feels smooth when the mill is integrated into the broader stack. Otherwise, it’s just an expensive machine that demands constant workarounds.

Finally, there is practice management and analytics. Without a central “nervous system,” even the best tech lives in silos. Metrics like chair time, material usage, crown remakes, and case acceptance reveal whether the digital stack is actually delivering on its promise or just adding complexity.

Interoperability is where health IT thinking really enters the operatory. In an ideal workflow, scans slide into design software without clumsy file juggling. Designs arrive at the mill pre‑tagged with the correct material, shade, and parameters. Once the case is done, key data flows back into analytics with minimal extra clicks.

When that doesn’t happen, staff end up reinventing the wheel every time. They manually rename files, copy data between systems, and chase down missing information. That adds friction, introduces errors, and quietly erodes the value digital dentistry was supposed to deliver in the first place.

Consider a regional clinic offering same-day CEREC dental crowns in East Texas. On the surface, the promise is simple: one visit instead of two, no temporary crown, fewer injections. Patients love that kind of convenience.

Underneath, though, the promise only works because the stack supports it. Scans are captured and queued in a consistent way. Design templates and material libraries are standardized. Milling units are maintained on a schedule, not only when something breaks. Assistants understand their role at every stage. Leadership tracks metrics like crown remakes, average appointment length, and patient satisfaction. The shiny equipment helps, but it is the workflow that makes the experience sustainable.

Dropping new tech into a practice without a plan is a fast way to burn out your team. Successful digital transitions treat implementation as a project, not a purchase. Training is staged and repeated, not reduced to a single vendor demo. Early cases are carefully chosen to be predictable and confidence‑building. Roles are clearly defined: who scans, who designs, who runs the mill, who reviews analytics.

Feedback loops matter too. When staff have a simple way to report friction points and suggest improvements, the stack gets better over time instead of becoming a rigid system everyone quietly resents. In that environment, people start to feel the benefits quickly: fewer retakes, clearer visuals for patient education, and less scrambling to track lab cases or shipping boxes.

Most practices don’t build their entire digital ecosystem in a single year. They start with scanners, then add design tools, then bring in milling or printing when the time is right. The key is to think like a systems architect even when budgets force gradual adoption.

Which services will gain the most from digitization right now? Where are you hearing the most patient frustration? What aspects of your workflow are hardest to measure? Answering those questions helps prioritize the next move, whether that means introducing chairside design, centralizing analytics, or piloting same‑day restorations in just one operatory.

In the end, a digital dentistry stack is successful when it quietly supports better care instead of demanding constant attention. When the right pieces are connected, promised experiences—like same-day CEREC dental crowns in East Texas —stop being marketing slogans and start becoming everyday reality for patients and teams alike.

The Cosmetic Dentistry Tech Explosion Facial scanners. Smile design software. Chairside milling units. Shade-matching cameras. The cosmetic dentistry tech stack is growing fast, and decision fatigue …

Posted Nov 14, 2025 Dental Care Dentistry

Connecting innovation decision makers to authoritative information, institutions, people and insights.

Medigy accurately delivers healthcare and technology information, news and insight from around the world.

Medigy surfaces the world's best crowdsourced health tech offerings with social interactions and peer reviews.

© 2026 Netspective Foundation, Inc. All Rights Reserved.

Built on Feb 17, 2026 at 4:40am